What is environmentally friendly die board?

Laser cutting machine is widely accepted and used in die board cutting industry, but it also caused some problems, like environment pollution because of smokes generated, cutting accuracy can’t get improved, die blade might drop out easily after long time used.

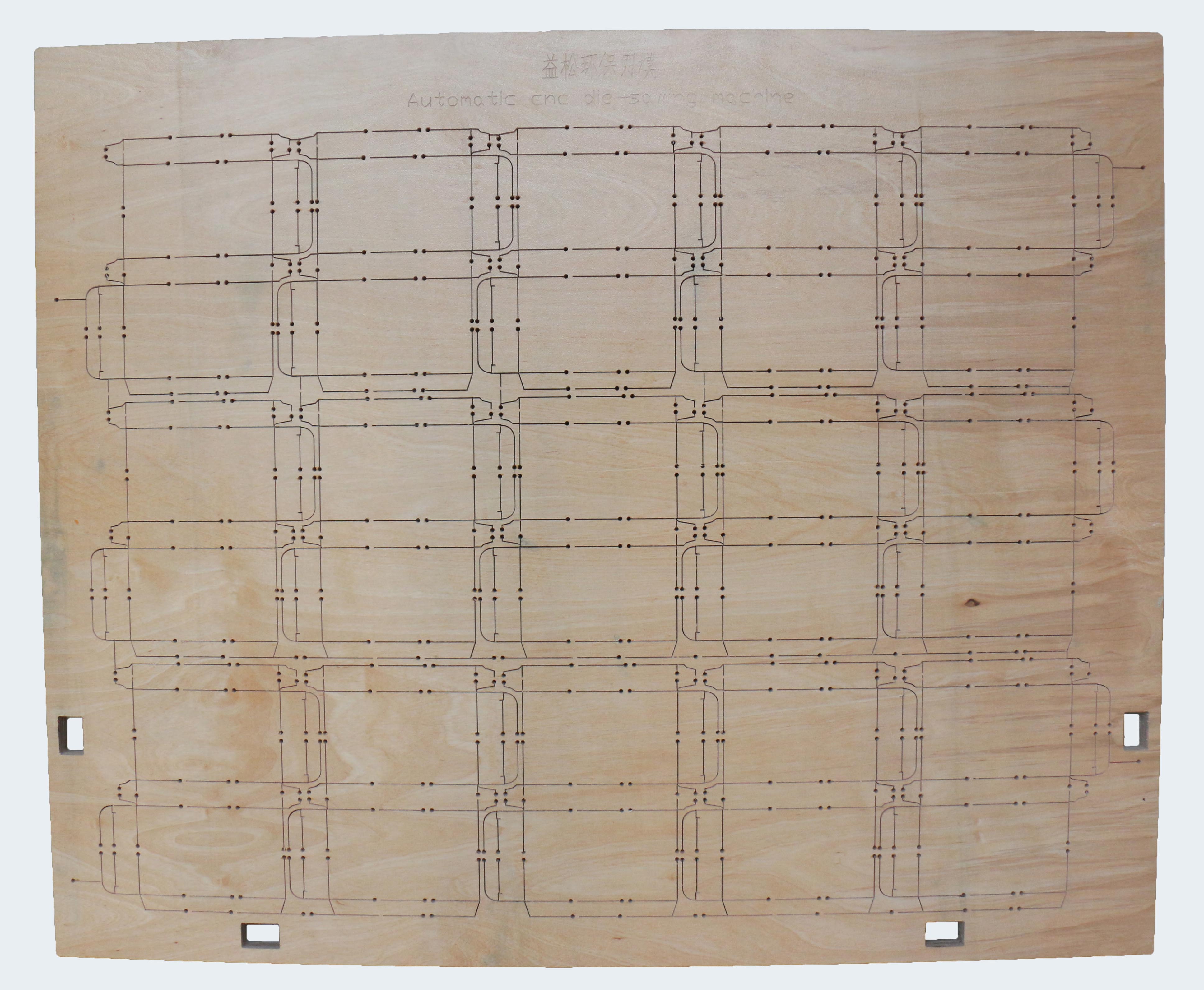

With almost 10 years’ efforts, we overcame lots of difficulties and obtained revolutionized technological breakthrough on die board cutting, we designed and developed automatic die board sawing machine. This new tech machine can solve the problems that exist in laser cutting.

Environmentally friendly die board is a new definition which aims to differ it from the laser-cutting die board. We call it “environmentally friendly” because the processing way to cut the die board is eco-friendly. During the cutting process, no smokes and toxic gas will be produced. And the advantages are more than this. Main features are as below.

Ø Environmentally friendly, no pollution, no toxic smoke and no smelly air;

Ø Saw blade cutting, without using laser;

Ø Automatic bridging, processing over 18mm’s die board at one time;

Ø High cutting precision and accuracy, high verticality, high clamping;

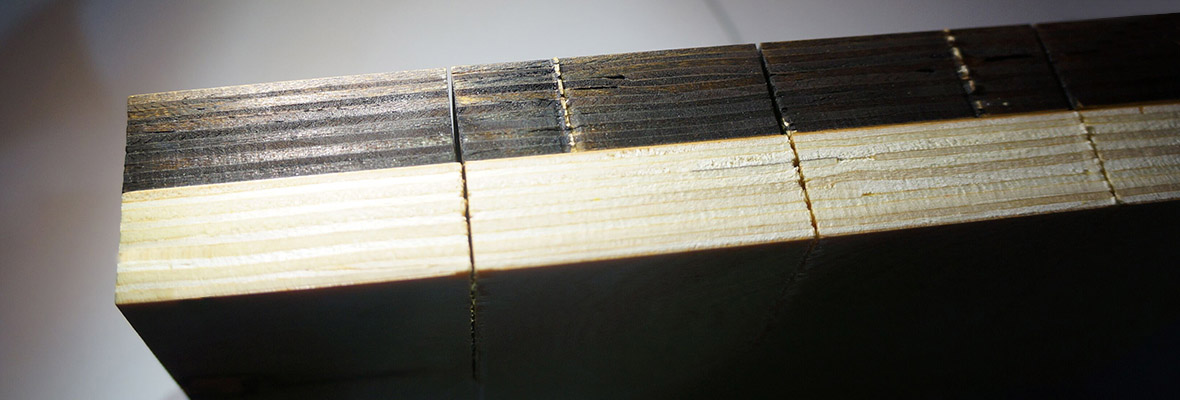

Ø Wooden fiber surface, no black edge, no carbonized layers;

Ø Lower cost and energy-saving, less than 1/5 of laser die board processing cost.

Based on above features, we call it “environmentally friendly die board”.

Environmentally friendly die board advantages are as below.

Ø Avoid the quality defects caused by laser cutting.

Ø Improve the tightness and clamping force of the kerf.

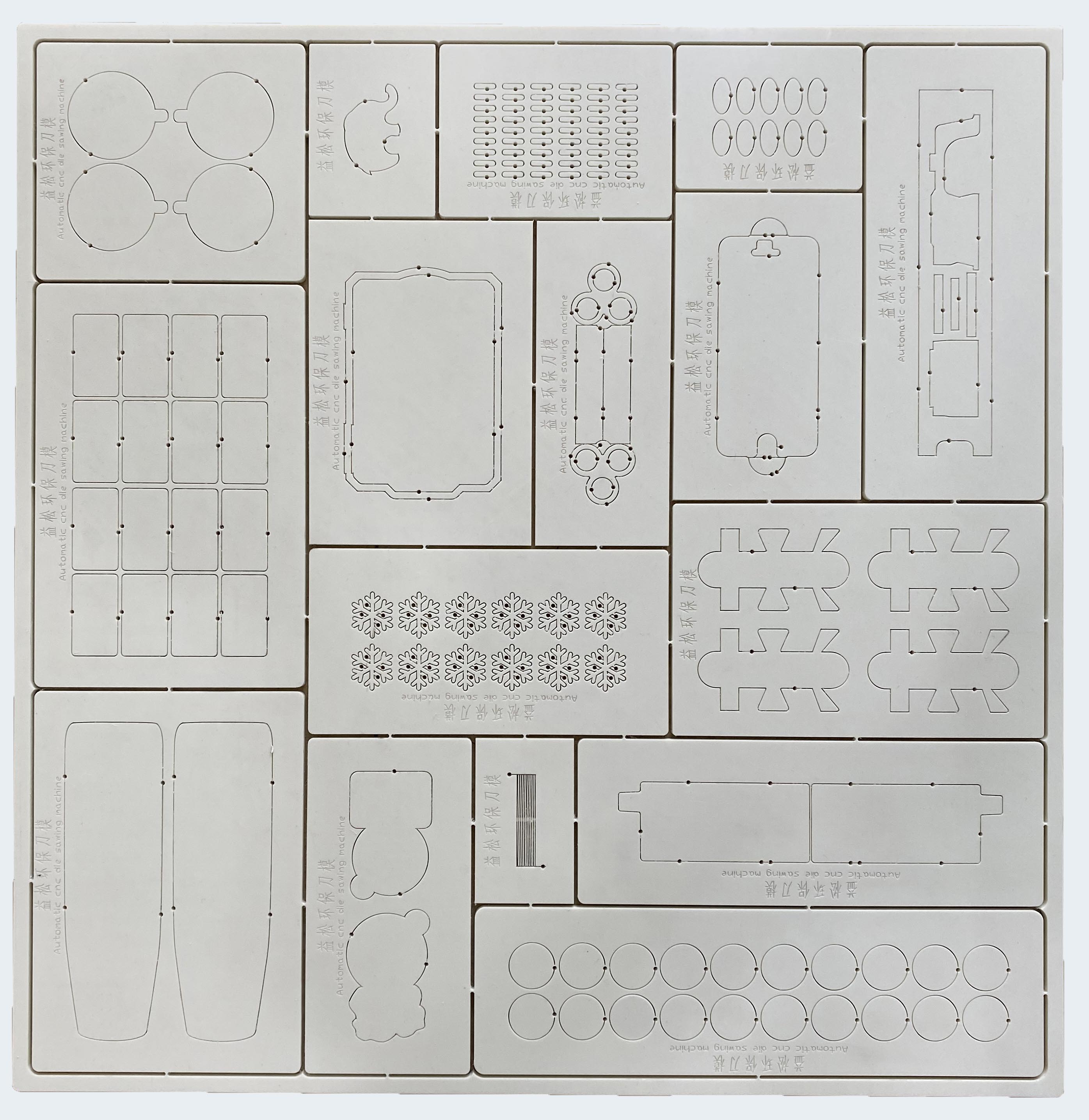

Ø Control and adjust the kerf width precisely.

Ø Ensure steady processing accuracy and precision.

Ø Solve the problem of bell-mouth and improve the verticality.

Ø Reduce distortion of die board .

Ø Solve the problem of laser trailing.

Ø No black edges on die board.

Our machine can really bring lots of benefits and values to printing and packaging industry, it can also help die board making factories and endusers get more competitive edges.