|

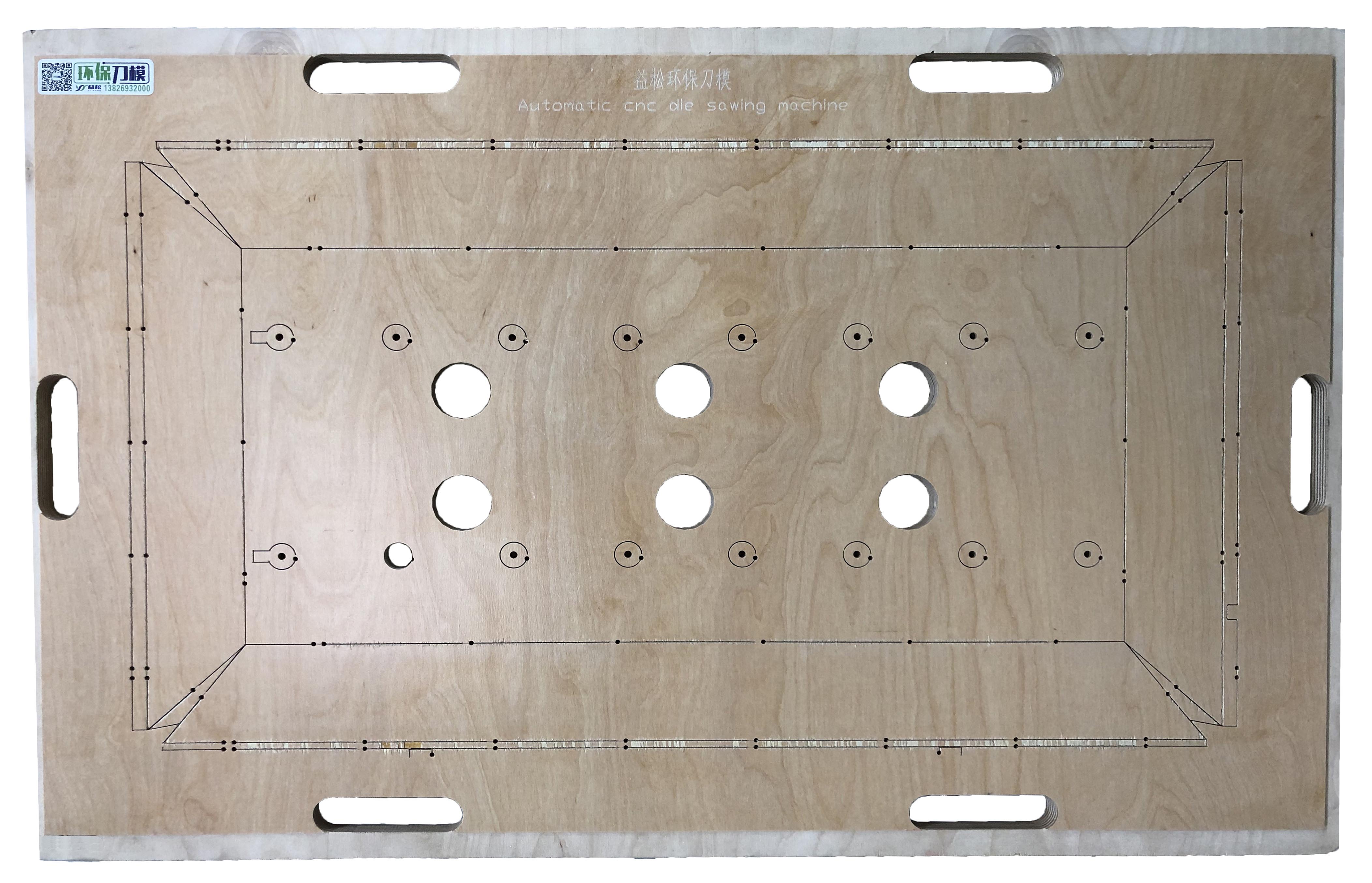

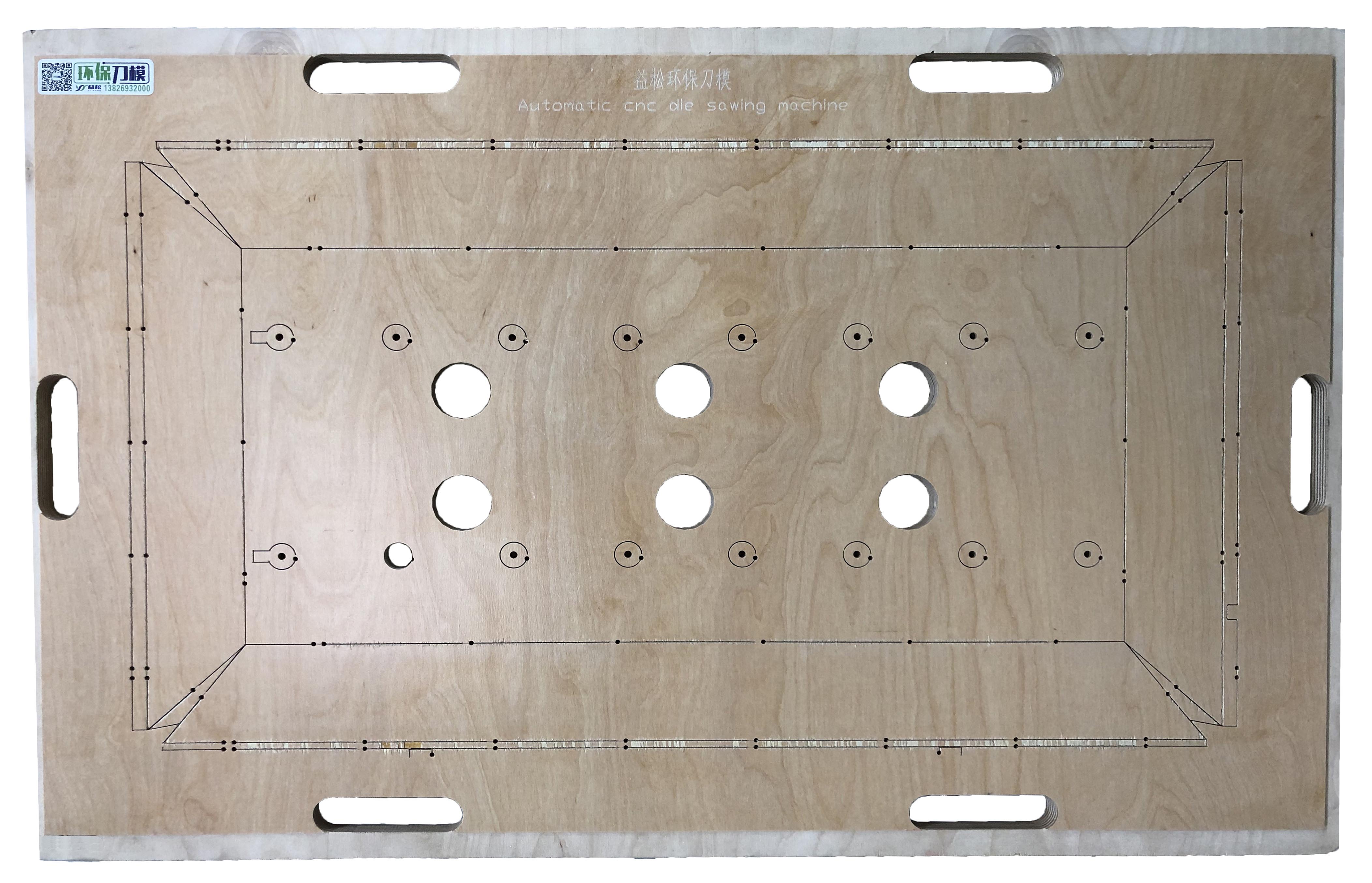

1.Accessible to process large-size photoelectric die board, no need import high end laser cutting machine; 2.No need to remove black edge which will be generated on laser die board 3.Kerf quality is much better than laser cutting die board

Competitive Edges Die Board Factories Can Gain From Making and Selling Eco-friendly Die Board

Avoid to be inspected by government environmental protection department

Improve the competitiveness of die board factory

1. Much low manufacturing cost than laser die board cutting machine.

2. Better precision than laser die board.

3. Better clamping than laser die board,die board using life can be longer.

4. Without black edge, it will be more acceptable to the customers.

Help die board manufacturers expand their business scope

1. Help die board producers’ manufacture high-end die board with lower

cost, to grow their business.

2. No start biding time, can deal with urgent orders and small orders.

3. Unique advantages make eco-friendly die board manufacturers more outstanding and it will benefit business development.

Decrease the manufacturing cost for die board factory

1.The whole production cost is 1/5 of laser die board cutting machine.

2. Saw blade is the only consumable item, which is cheap and easy to get replaced.

3. The electricity consumption is 1/10 of high-power laser cutting machine.

Reduce the cost of maintenance and installation

Eco-friendly die board saw cutting machine only consists of CNC sawing machine and an air compressor. It’s different from the laser die board cutting machine’s configuration, which is complex and costs much for maintenance and installation.

Improve security guarantee for employees & enterprises

Easy-operating, easy-learning and easy-training, technician would like the machine better

Eliminate environmental pollution & health impacts