By Owen

By Owen  2018-05-31

2018-05-31 laser die cutting machine,

laser die cutter,

laser die cutting,

laser die cutting machine,

laser die cutter,

laser die cutting,

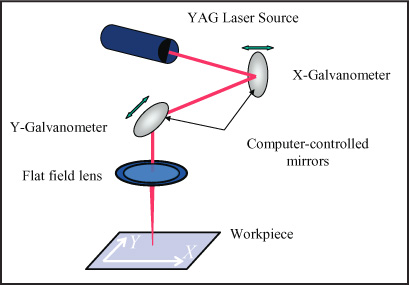

The Galvo laser die cutter system has made the most significant progress in the area of laser die cutting in the past few years, especially in the label, medical equipment and nameplate industries. The Galvo laser head remains stationary above the mesh or sheet material, and the mirror inside the head is fine-tuned to redirect the laser path onto the substrate. Because the laser source changes direction through the mirror, the Galvo laser die cutting machine head is cutting the angle, so the thinner the material, the better. This is in contrast to a gantry laser die cutter, which always moves directly above the cutting area and points directly downwards.

The Galvo laser die cutting machine system is currently being marketed as a sheet, roll, or combination sheet and roll feed system. They are used in a variety of materials, including polyesters, plastic films, paper, adhesives, and abrasives. One of the few materials that cannot be regularly cut on a laser die cutter system is PVC, because gas and substrate discoloration occur when the material is burned when the material is cut. The Galvo laser die cutter system also adds rotary die cutting stations and laser markings to its product portfolio while running on-line with digital presses. The ability to complete a new job in the morning and transport finished parts in the afternoon makes the laser die cutting system a lucrative opportunity for many printers.