By Rachel Shieh

By Rachel Shieh  2018-04-29

2018-04-29 die making,

laser die cutting machine,

die making process,

die cutting,

die making,

laser die cutting machine,

die making process,

die cutting,

Laser die cutting machine is widely used in die making. For die making, mainly laser die cutting machine and steel rule die bending machine are involved. Also our company produces die sawing machine which can be replacement for laser die cutting machine.

Step 1. Drawing

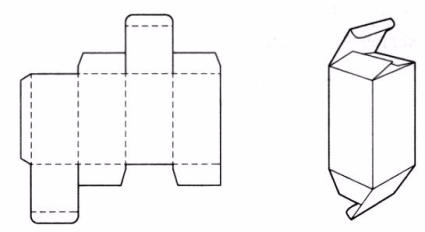

The die-cut drawing design is a full-size carton development after the printing process, and is the first key link of the die-cut production. In the printing plate making process, if a full-page imposition system is used, the die-cutting diagram can be directly output in the printing plate-making process, which can effectively ensure that the printing plate and the die-cutting die have a unified standard. In the case of a carton printing plate process, if a manual film is used for imposition, the die cutting process needs to draw a die cut according to the actual size of the sample layout.

In the process of drawing die-cutting drawings, the positions of the cutting cutters and the location of the creasing lines shall be clearly marked according to the national carton drawing standards. In order to ensure that the die-cutting die does not disperse during the plate-making process, the graphics must be enclosed in a large area. Leave more than two places and do not saw them. This location is usually called a bridge. The width of the bridge can be designed to be 3-6 mm for small plates and 8-9 mm for large plates.

Step 2. Die Making

The materials used for the die making include wooden plywood, high-density board, and bakelite board. Currently, plywood is commonly used. The thickness of wooden plywood is about 18 millimeters. Hardwood plywood has a higher durability.

Cutting dies can use different cutting methods. They include die sawing machine and laser die cutting machine.

Die sawing machine is one of the way to make die. The work of the die sawing machine is to use the up and down reciprocating motion of the saw blade to process the narrow slits for the die cutters and creasing lines on die with a special ultra-narrow saw blade. The thickness of the saw blade is equal to the thickness of the die cutter or creasing line in the corresponding position. The saw blade with a thickness of 0.7-2.0 mm and a width of 1.5-3.0 mm is commonly used. The saw bed is equipped with an electric drill and can be drilled on die plate. After drilling, the saw blade cut through the hole.

The laser die cutting machine is carried out on a computer-controlled laser cutting machine. It is a method in which the laser is used as an energy source to cut the material of the die by the high temperature generated by the laser. The laser die cutting machine first needs to input the full-page die cutting diagram into the computer, and the computer controls the laser head to cut the die.

Laser die cutting machine uses computer control, the cutting accuracy of die cutting is very high. However, there are many factors that affect the cutting quality in the laser die cutting process. Therefore, in actual production, it is extremely important to draw lessons from past experience to determine the processing effect. The main disadvantage of laser cutting is that laser cutting machines are expensive, and they are usually made by professional manufacturers.