By Esperanza

By Esperanza  2018-12-29

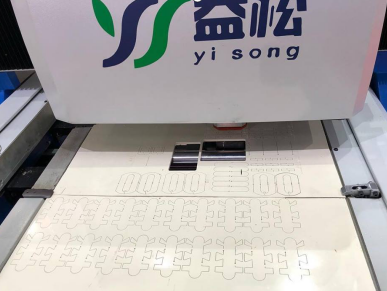

2018-12-29 die sawing machine,

automatic die sawing mahcine,

die sawing machine,

automatic die sawing mahcine,

Precise control and adjustment of the slit width.

When machining laser cutters with lasers, the seam control is inaccurate. The operator's experience is used to adjust the laser beam and laser power to achieve the purpose of fuzzy adjustment of the slit width. The environmentally friendly die board is processed by saw blade and passed through the saw blade. The three elements of the inherent width, processing speed and saw blade vibration frequency can precisely control the width of the slit and realize the quantitative management and control of the die board manufacturing quality.

Improve the stability of processing progress.

When laser processing a laser die, the output power is closely related to the laser generator, laser tube, and laser reflecting lens. These components are prone to aging during use, because of the attenuation and instability of the output power, resulting in inconsistent variations in the width of the cutting slit, resulting in unstable mold quality. The environmentally friendly die cutter is machined with a saw blade, and the influence of the saw blade on the slit width of the die cutter is negligible, maintaining the stability of the slit width.