By Esperanza

By Esperanza  2018-10-30

2018-10-30 laser die cutting machine,

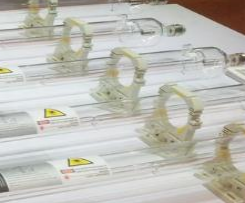

laser tube,

laser die cutting machine,

laser tube,

After the laser tube which applied in the laser die cutting machine is operated for a period of time, a large amount of dirt adheres to the wall of the water tube of the laser tube and the water-passing water pipe due to water quality, dust, deposition of soot and dust of the cutting material, and microbial growth for the laser die cutting machine. The adhesion of these dirt to the pipe wall affects the cooling water to take away the temperature inside the laser tube, causing the laser tube power spot to be affected, and even causing the laser tube to burst in severe cases for the laser die cutting machine.

Based on the above situation, our company recommends using the chiller and regularly maintenance for the laser die cutting machine according to the following contents, as follows:

Every month: Check the level of coolant in the chiller tank in the laser die cutting machine.

Every three months: replace the cooling water. Check the condition of the chiller condenser of the laser die cutting machine.

Every six months: Install a new deionization filter and cooling water filter. Remve dust and debris from high-voltage power supplies, laser tubes, and chillers for the laser die cutting machine.

If the inner wall of your laser tube is contaminated, please clean it as follows:

1. Ensure that the positive and negative wires of the laser tube for the laser die cutting machine and the cooling water inlet and outlet pipes are removed when the power is off for the laser die cutting machine.

2. Drain the cooling water in the water-cooled tube of the laser tube, and seal the output end of the laser tube for the laser die cutting machine withed, and shake it to release the aqueous solution for the laser die cutting machine. a tape to avoid water contamination of the output lens during cleaning for the laser die cutting machine.

3. Debug the hydrofluoric acid solution, adjust the ratio of 1:1000 (hydrofluoric acid: water), and inject the debugged aqueous solution (or use the glass cleaning agent) into the laser tube cooling tube for the laser die cutting machine.

4. Place the flat surface for 30 minutes, shake it evenly after being placed, and shake it to release the aqueous solution for the laser die cutting machine.